Groundbreaking Zero-Vibration KNOBGEAR Range Extender Technology Successfully Tested

Transforming Mobility: The KNOBGEAR Range Extender for Enhanced Efficiency and Sustainability in Electric and Hybrid Vehicles Ready for Market Deployment

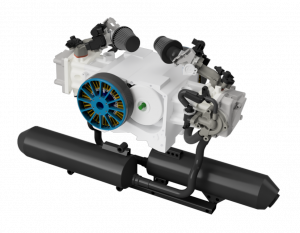

PRAGUE, CZECH REPUBLIC, November 1, 2024 /EINPresswire.com/ -- As the automotive industry moves towards sustainability, range extender technology for electric vehicles (EVs) and hybrid electric vehicles (HEVs) represents a significant leap forward. KNOBGEAR's Range Extender is designed to increase efficiency and longevity by providing an economically viable and completely vibration-free additional power source when the battery becomes low, allowing longer distances to be driven without fear of battery drain.

Technology Behind the Range Extender

The KNOBGEAR Range Extender is a testament to engineering excellence, incorporating a motor-generator system exceptional for its vibration-free operation. This is achieved through a meticulous design that includes symmetry and synchronization gear, ensuring seamless functionality across various operational conditions.

Symmetrical Design

The core of the Range Extender's zero-vibration capability lies in its symmetrical design. This approach ensures that every mechanical component is perfectly balanced, preventing the onset of disruptive vibrations. The symmetry not only enhances user comfort but also contributes to the durability and longevity of the system by reducing mechanical stress.

Synchronized Crankshafts

A standout feature of the Range Extender is its pair of synchronized crankshafts. These crankshafts are designed to rotate in opposite directions, a configuration that effectively cancels out all inertial forces that typically generate vibrations. This counter-rotating mechanism ensures that all forces and moments created by the pistons, piston rods, and other moving components are perfectly balanced, maintaining stability and contributing to the system's zero-vibration promise.

Ensuring Equal Moment of Inertia

The issue of modern engines is vibrations induced by the combustion cycle. This issue is ideally addressed by the KNOBGEAR Range Extender design. One of the fundamental principles behind zero-vibration operation is achieving precise parity of moment of inertia between its two crankshafts. Equal moment of inertia is crucial for maintaining equilibrium and ensuring that the system operates without introducing vibrations. By achieving inertia parity, the Range Extender minimizes the transfer of vibrational forces to the vehicle structure, which is essential for maintaining overall stability and user comfort. This parity is achieved by implementing two identical generators, one for each crankshaft. This is advantageous from a low-profile view. Alternatively, one generator may be implemented on one crankshaft and a flywheel on the second crankshaft. Achieving these zero-vibration properties involves advanced engineering techniques that include the precise calculation of mass distribution and rotational dynamics. This meticulous attention to detail not only enhances the reliability and performance of the system but also supports its application in sensitive environments where vibration-free operation is crucial.

“Through these innovative design elements, our Range Extender sets a new standard in motor-generator technology, offering a significant leap forward in the pursuit of sustainable and efficient transportation solutions. A significant advantage for potential buyers from the automotive or aerospace industry is the easy implementation and patent protection in most parts of the world,” says Václav Knob, chief engineer and owner of the KNOBGEAR trademark.

Truly Zero Vibration - Look at Our Coin Test

Vibrations in internal combustion engines, traditionally a significant challenge, have been thoroughly addressed in the KNOBGEAR Range Extender. We know that the world and internet are full of miraculous and fantasy simulations and calculations. Therefore, we decided to demonstrate impressive results, eliminating all possible doubts with The Coin Test. This Coin Test further exemplifies this capability, showcasing the extender's stability and zero vibration levels in all operation modes, including start and stop procedures. This low level of vibration is crucial for applications requiring minimal mechanical disruptions, such as those involving sensitive instrumentation in aviation.

Applications & Studies - Integration and Compatibility

The low-profile design of the Range Extender simplifies its integration into existing vehicle architectures. By utilizing components from contemporary single-cylinder engines, the Range Extender ensures not only rapid development but also cost-effectiveness. This thoughtful design means manufacturers can easily adopt and implement the Range Extender into their designs, paving the way for enhanced performance and greater efficiency in both electric and hybrid vehicles.

The versatility of KNOBGEAR’s Range Extender is evident in its wide array of applications. It acts as a pivotal component in transforming electric vehicles into robust hybrids, providing extended range and reliability. In hybrid electric vehicles, the extender ensures uninterrupted mobility, a crucial advantage in areas with limited charging infrastructure. Moreover, its application extends to ultralight aircraft and special machinery, where its lightweight and zero-vibration characteristics offer enhanced flight performance and safety. By replacing traditional internal combustion engines, the Range Extender significantly reduces emissions, aligning with the global shift towards sustainable aviation solutions.

As the automotive and aviation industries evolve, the KNOBGEAR Range Extender stands out as a revolutionary innovation addressing the limitations of current electric and hybrid systems. By offering a solution that combines zero vibration with efficient power delivery, it not only enhances vehicle universality but also contributes to a more sustainable future. For more information, visit the official KNOBGEAR website.

About KNOBGEAR Trademark

KNOBGEAR specializes in designing and manufacturing advanced automotive components, focusing on innovative engine technologies and high-performance racing gearboxes. Our offerings include Racing Gearboxes, Sequential Shifters. Our current development projects are Range Extenders and Birotary Engines. Backed by numerous patents, our commitment to innovation ensures that we deliver products meeting the highest standards of quality and performance.

Václav Pieter

KNOBGEAR

email us here

Visit us on social media:

LinkedIn

YouTube

The Range Extender Engine: Coin Test Demonstration

Distribution channels: Automotive Industry, Aviation & Aerospace Industry, Business & Economy, Manufacturing, Military Industry, Technology ...

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release